SPITZENQUALITÄT. VIELFACH ZERTIFIZIERT.

FÜR HÖCHSTE ANSPRÜCHE. T+H

ZERTIFIKATE

Zertifikate von unabhängiger Seite belegen die herausragende Qualität aus dem Hause T+H. Hochentwickelte Fertigungsanlagen, modernste Messgeräte und sorgfältige Dokumentation sorgen für erstklassige Produkte.

- DIN EN ISO 9001

- DIN EN 9100

- IATF 16949

- DIN EN ISO 14001

SPEZIALPROZESSE

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

KVP

Das KVP-Management bei T+H sorgt für die ständige Optimierung aller Unternehmensbereiche und Prozesse. Folgende Themen sind uns ganz besonders wichtig:

- Implementierung neuer Technologien

- Aus- und Weiterbildung

- Energiemanagement

- Umweltschutz und nachhaltiges Handeln

- Abfallmanagement

- Arbeitssicherheit

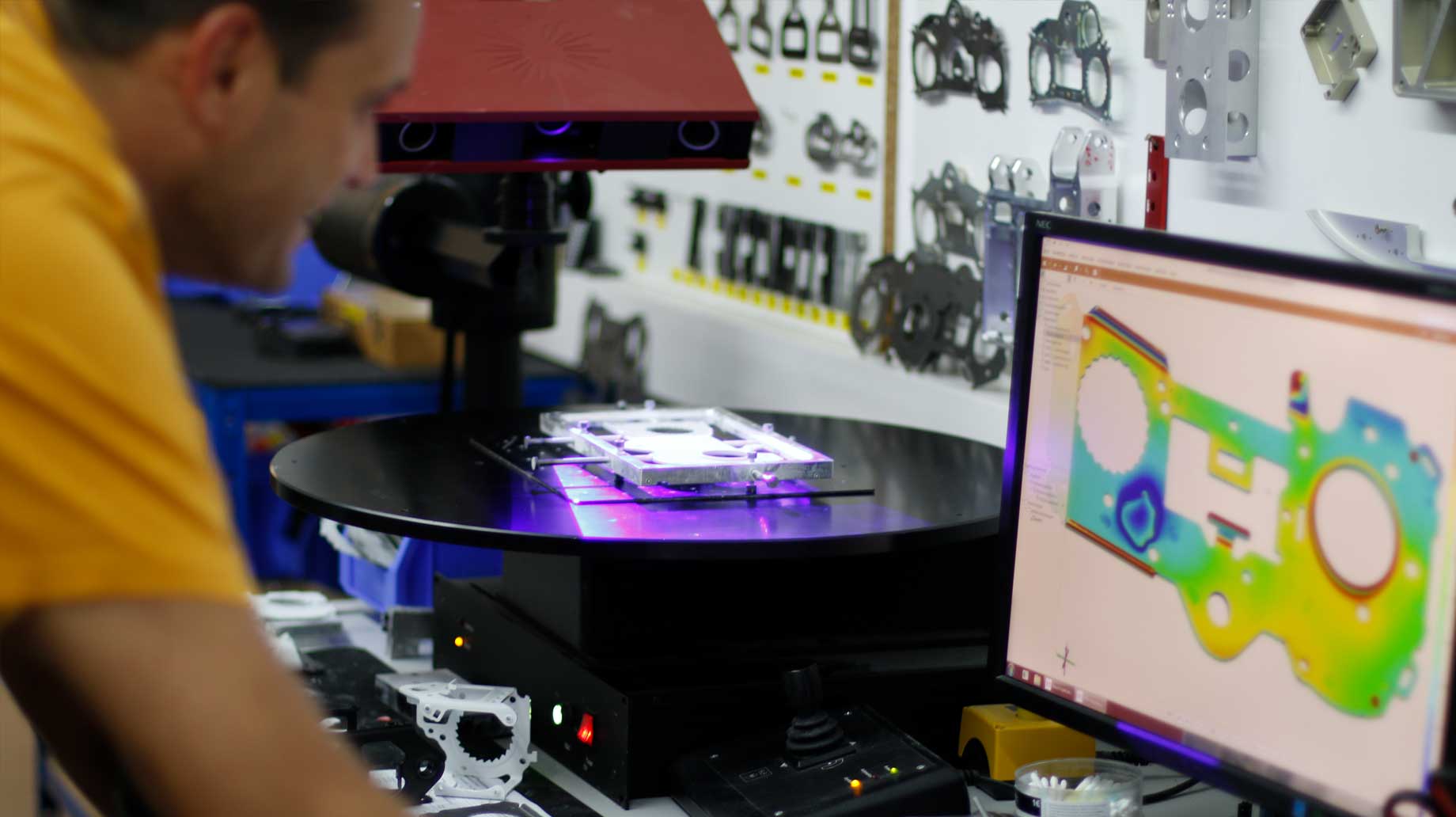

MESSMETHODEN

Folgende Messsysteme /-methoden kommen bei T+H zum Einsatz:

- 3D Koordinatenmessmaschinen taktil / optisch

- 3D-Digitalisierer

- Zugprüfungen

- Salzsprühnebeltests

- Schichtdickenmessungen

- Leitfähigkeitsmessungen

- Glanzgrad- und Farbmessungen

- Gitterschnittprüfung

- Badanalysen

- etc

„Vertrauenswürdige Partner erkennen Sie an planbaren Ergebnissen. T+H gibt Ihnen die Sicherheit, dass Materialien und Fertigungsverfahren strengsten Qualitätskriterien standhalten.“

English

English