[/vc_column_text][/vc_column][/vc_row]

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

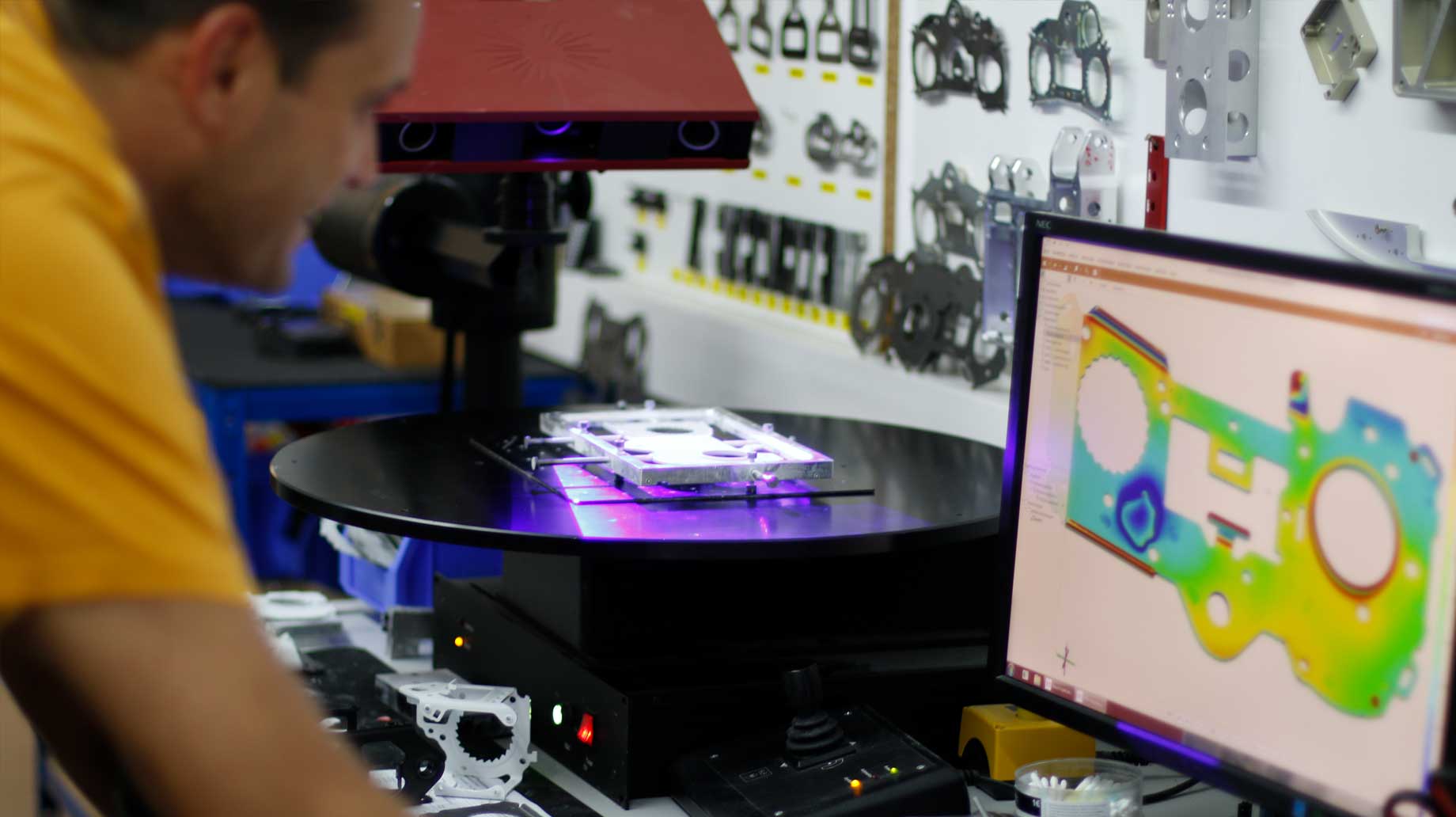

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

STOP QUALITY. CERTIFIED IN MANY RESPECTS.

FOR THE HIGHEST DEMANDS. T+H

CERTIFICATES

Independently issued certificates are proof of the outstanding quality delivered by T+H. Sophisticated manufacturing facilities, the most modern measuring instruments, and accurate documentation ensure you get first-rate products.

- DIN EN ISO 9001

- DIN EN 9100

- ISO TS 16949

- DIN EN ISO 14001

- ISO 50001

SPECIAL PROCESSES

Special processes approved by Airbus

- DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES DIMPLING OF SHEETS FOR ATTACHING PARTS

- INSTALLATION OF ANCHOR NUTS

- INSTALLATION OF FASTENER AND NUTS

- INSTALLATION OF HELICAL THREADED INSERTS TIGHTENING OF SCREWS AND NUTS

- PRESSING AND INSERTION OF BUSHES AND BEARINGS WET INSTALLATION OF FASTENERS

- TREATMENT OF SOLID ALUMINIUM RIVETS PRIOR TO INSTALLATION INSTALLATION OF RIVETS WITH AN AUTOMATIC RIVETER

- INSTALLATION OF HI-LOKS

- INSTALLATION OF CLOSE-TOLERANCE BOLTS HI-LITE, VERI-LITE INSTALLATION OF NAS BLIND RIVETS AND MS-NASM-ANS-EN BLIND BOLTS

- INSTALLATION OF CHERRYMAX BLIND RIVETS

- INSTALLATION OF POP BLIND RIVETS

- BONDING OF NON-STRUCTURAL CONNECTIONS

- APPLICATION OF SEALING COMPOUNDS

- PRETREA TMENT OF NON-STRUCTURAL JOINTS FOR BONDING

- PRETREATMENT OF POLYAMIDE FOR BONDING

- CHROMA TING OF ALUMINIUM AND ALUMINIUM ALLOY

- SEALING OF ANODIZED LA YERS

- DC SULPHURIC ACID COLOR ANODIZING WITH SEALING

- CHROMIC ACID ANODIZING

- COATING WITH W ASH PRIMER

- COATING WITH TWO-COMPONENT PRIMER EP-BASED

- COATING WITH TWO-COMPONENT PRIMER CHROMATE-FREE

- COATING WITH PUR-BASED TOP COAT

- COATING WITH ANTI-SLIP PAINT

- APPLICATION OF ELASTIC PROTECTIVE COATINGS

- ASSEMBLY WITH DUROPLASTIC ANTI-CORROSION COMPOUND, CHROMATE-FREE PRESERVATION OF CUT EDGES

- PRESERVATION OF RIVET ROWS

- APPLICATION OF FILLERS

- COATING WITH PAINTS AND VARNISHES, GENERAL

- PAINT COA TING IN INTERIOR FURNISHING

- REPAIR OF PAINT COATINGS ON METALLIC AND NON-METALLIC SURFACES

- HEAT TREA TMENT OF ALUMINIUM

- DEHYDROGENA TION OF STEELS

- ELECTRICAL BONDING

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- ATP 2016-09-29

- PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS INSTALLATION OF BLIND

- BOLTS AND BLIND RIVETS – PULL-TYPE GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS INSTALLATION OF PARALLEL SHANK THREADED

- FASTENERS CHROMIC ACID ANODIZING OF ALUMINIUM ALLOYS

- SULPHURIC ACID ANODISING OF ALUMINIUM ALLOYS

- TSA OF ALUMINIUM ALLOYS FOR CORROSION PROTECTION AND PAINT PRETREATMENT CHEMICAL CONVERSION COA TING

- PASSIVATION OF CORROSION RESISTANT STEEL

- DIMPLING

- APPLICATION OF ANTI-STATIC PAINTS ON COMPOSITE PARTS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF EXTERNAL PAINT SYSTEMS

- APPLICATION OF DECORATIVE INTERIOR PAINT

- APPLICATION OF STRUCTURAL PAINTS

- REWORK OF PAINTS ON METALLIC AND NON-METALLIC STRUCTURAL PARTS APPLICATION OF GAP FILLER – EASY TO REMOVE

- SEALING OF AIRCRAFT STRUCTURE

- SURFACE PROTECTION OF FASTENERS AND SEALANTS BY APPLICATION OF VARNISH WET INSTALLATION OF FASTENERS

- APPLICATION OF NON HARDENING JOINTING COMPOUNDS

- APPLICATION OF LOW ADHESION SEALANTS

- ELECTRICAL BONDING

- SURFACE PREPARATION PRIOR TO EXTERNAL PAINT APPLICATION

CIP

T+H’s CIP management assists us in continuously optimizing all parts of the company, including the processes. The following subjects are especially important:

- Implementation of new technologies

- Education and training

- Energy management

- Protection of the environment and sustainability

- Waste management

- Occupational safety

MEASURING METHODS

These are the measuring methods used by T+H:

- ATOS – optical 3D scanner

- 3D manual coordinate measuring machine – Tesa Micro MS454

- Werth Scope Check

- Various digital height gauges

- Schichtdickenmessgerät

- Coating gauge

- Gloss meter

“You can recognize trustworthy partners by their projectable results. T+H gives you the certainty that the materials and the manufacturing processes comply with the strictest quality criteria.”

Deutsch

Deutsch